CNC SETTER / OPERATOR

£24K – Permanent - Birmingham

JOB DESCRIPTION

Reports to: Production Manager.

Purpose of the Job:

To lead the on line setting and operating of machines for existing and new product introduction

Duties & Responsibilities:

- Compliance with all relevant Health and Safety and Legislative requirements.

- Fully appreciate the manufacturing process and capability of Andover Precision.

- A full appreciation of the Cellular manufacturing organisation within the company.

- Fully appreciate the machine types and capabilities.

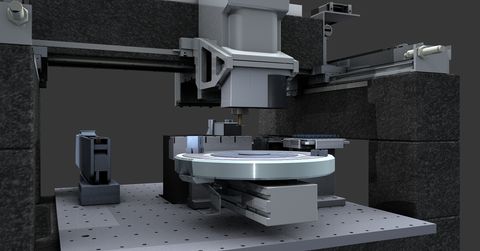

- Setting and operating CNC Machines.

- Take all available customer information / drawings / standards etc. to fully satisfy the customer requirement.

- Complete work in a timely manner to the required quality standard.

KPI’s & Controls:

- Ratio of planned to actual hours.

- Correct tooling and materials used.

- Ensure that the most economical process is achieved in terms of speed, metal removal & tooling.

- Components per hour.

- Ensuring quality workmanship in line with best practise.

- Ensuring first off inspections are undertaken by the operators to ensure programmes are correctly applied.

- Close liaison with the Quality team in order that problem areas can be identified as soon as possible with a view to corrective and preventive action being carried out.

- Assistance in resolving setting problems.

- Close liaison with the Production Manager / Engineer regarding production schedule requirements.

- The appropriate processing and manufacturing times.

- Non value added personal movement and try to eliminate it wherever possible.

- Non value added transport movement and try to eliminate it wherever possible.

- The use of only approved materials and products.

- The use of the 7 quality tools initiative.

- Order requirements and produce the correct batch size.

- The Kanban initiative.

PERSON SPECIFICATION

Experience

Essential:

- Fully trained CNC Setter / Operator.

- Minimum 5 years’ experience in the 2/3 axis setting and operating of complex machined components for the Aerospace or similar Industries.

- CNC operating experience.

- Fully appreciate.

- Machine types and their capabilities.

Desirable:

- Experience in the 4/5 axis setting and operating of complex machined components

Qualifications/Training

Essential:

- Engineering Qualification (ONC, BTEC, City & Guilds).

- Evidence of continued professional study.

- Having completed an engineering Apprenticeship.

- Education to GCSE level with Maths and English at Grades A*-C or equivalent with excellent numeracy and literacy skills.

Desirable:

- Programming qualification or working towards (e.g. City and Guilds).

Practical skills

Essential:

- Outstanding organisational skills.

- Interpersonal skills.

- Communication skills.

- Numeracy skills.

Desirable:

A proven track record of:

- Using own initiative within defined procedures and policies.

- Presenting information in a logical, clear and concise format and communicating this effectively, both verbally and in writing.

- Working collaboratively with a range of colleagues.

- Managing own workload.

- Identifying priorities quickly and accurately and ensuring that deadlines are met.

- Analysing data and information and advising on findings and solutions.